Mineral water /drinking water/natural water/ spring water are terms used for the various bottled water being marketed in the world. The main feature in all these types of water are that they are made safer and more reliable for the human consumption. They differ major in its source and the treatment being employed before bottling.

Water treatment for Mineral Water Bottling is completed in four phases:

- At the first level, we are required to remove sand, dirt, clay, rust, and all other suspended particles from the water. For this purpose, we use cartridge filter, sand filter, bag filters, multimedia filter etc. to bring water quality acceptable for further processing.

- The second stage involves the treatment by chlorination, and activated carbon filtration. With this, water is made free from all organic chemicals, removes bad taste & odor, color smell etc. With this the taste of water improves to an acceptable level.

- In the third phase, the drinking water manufactures are setting their TDS target to a suitable limit of 150 – 200 ppm. This can be accomplished by using demineralization plant, distillation unit and reverse osmosis (RO) unit. Among all of the above three techniques, reverse osmosis systems gives the best results in compared on the basis of ease of operation, operating cost, maintenance cost, consistent product water quality, etc.

- The last and the most important phase of bottle water production is to remove / kill the bacteria & viruses from the water before filling to make it safe for human consumption. This can be accomplished by the following most common methods; chlorination, UV sterilization, ultrafiltration, and ozone treatment. Now a day’s ultrafiltration systems are mainly used with all mineral water plant to reduce to microbe load.

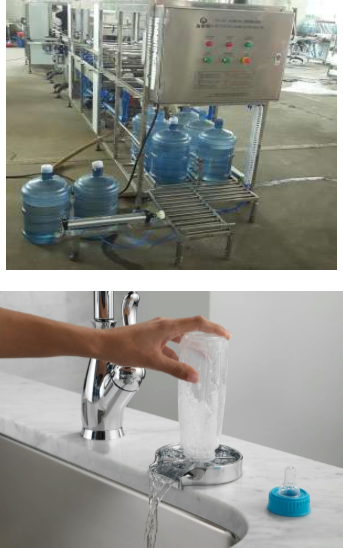

In addition to complete bottled water treatment plant Water 2000, Inc, Inc also supplies complete bottling system for varying capacities (0.6 lit, 1.5 lit, 3 lit, 12 lit and 5 gallons bottles) including:

- Rinser

- Filler

- Capper

- Neck Sealer

- Conveyer Belts

- Collection Tables etc.